CASE STUDY: Duke Construction used Air Energy “The Rack” ER systems to increase tenant comfort level in the space and reduce energy costs.

Duke Construction wanted the design HVAC contractor to explore new ways to upgrade the low heating efficiencies of standard unit heaters and the constant moving of these heaters in their Type 2 spec buildings.

PROBLEM: Older unit heaters were not providing the comfort level required by tenants for their employees.

PROBLEM: On their Type 2 buildings, Duke had always used unit heaters in their spaces for heating. As a heating system, unit heaters were not only not economical to operate; they were not providing the comfort level required by their tenants for their employees.

SOLUTION: By putting The Rack™ ER systems in the corners, they eliminated any future need to move the systems regardless of how the building space was subdivided. Along with not moving the systems, they increased the comfort level in the space and reduced the energy costs to the tenants. View additional “The Rack” case studies here.

In this economy – energy efficient, quality built, and affordable ventilation and air distribution products are critical to keeping building temperatures consistent and energy costs low. Duke Construction knows about cost saving The Rack™ ER Units – and now you do too.

SOLUTION: The Rack™ increased the comfort level in the space and reduced the energy costs to the tenants.

To learn more contact the Air Energy Systems sales office at (317) 290-8500 .

The Rack™ models are available in four sizes:

- ER-130-200 : 9,000 cfm – 200,000 btu/hr

- ER-230-400 : 18,000 cfm – 400,000 btu/hr

- ER-142-400 : 16,500 cfm – 400,000 btu/hr

- ER-242-800 : 33,000 cfm – 800,000 btu/hr

![]() Download a copy of The Rack™ brochure.

Download a copy of The Rack™ brochure.

Ideal for Metal Buildings – The Rack™…

Ideal for Metal Buildings – The Rack™…

- Reduces the need for expensive roof structural steel.

- Eliminates roof penetration which causes roof leaks.

- Decreases the quantity of units needed to distribute the conditioned air evenly throughout the space.

- Maintains consistent temperatures throughout the work environment eliminating the need for expensive discharge duct work.

- Lowers installation costs with gas and electrical piping.

- Saves utility expenses in both natural gas and electrical consumption.

- Our Case Studies prove The Rack™ is the best solution for Metal Buildings.

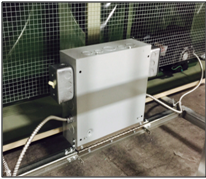

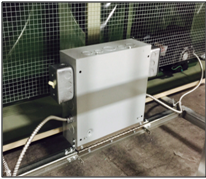

The Newly Renovated Rack

- Switching from Angle Iron to a Galvanized Tube Steel Frame led to lighter overall weight, elimination of wooden pallet, cheaper shipping costs and quicker installation.

- Adjustable Brackets on the back frame allows for The Rack to accommodate all styles of unit heaters, effortless installation and easier service entry.

- A completely redesigned Control Panel resulted in clear access to controls, straightforward wiring process and speedier service time.

- Our New Control Panel will ship straight up. Once on the jobsite the panel will hinge down for wiring, service and easy access.

*New Rack provides convenient carrying

- Our Control Panel has UL approved fittings, whips, switches, terminal block and housing.

*Control Panel in Shipping Position

The Rack™ Energy Rotation System – Guarantees ENERGY SAVINGS while maintaining consistent BUILDING TEMPERATURE.

Features:

- High Energy Savings

- Consistent Building Temperature

- Low Installation Cost

- No Loss of Valuable Floor Space

- Quiet Operation

- Low Maintenance

- Fresh Air Intake Option

In this economy – energy efficient, quality built, and affordable ventilation and air distribution products are critical to keeping building temperatures consistent and energy costs low.

To learn more visit AESRack.com, or cotact the Air Energy Systems sales office at (317) 290-8500 or email contact form.

06 Jul / 2016

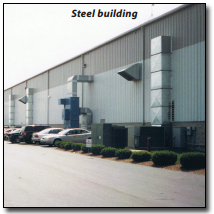

The Rack™ is Ideal for Steel Buildings

The Rack™ is Ideal for Steel Buildings

The Rack™ is Ideal for Steel Buildings

The Rack™…

- Reduces the need for expensive roof structural steel.

- Eliminates roof penetration which causes roof leaks.

- Decreases the quantity of units needed to distribute the conditioned air evenly throughout the space.

- Maintains consistent temperatures throughout the work environment eliminating the need for expensive discharge duct work.

- Lowers installation costs with gas and electrical piping.

- Saves utility expenses in both natural gas and electrical consumption.

- Case Studies prove The Rack™ is the best solution for Metal Buildings.

![]() Download a copy of The Rack™ brochure.

Download a copy of The Rack™ brochure.

The Newly 2016 Renovated Rack

- Switching from Angle Iron to a Galvanized Tube Steel Frame led to lighter overall weight, elimination of wooden pallet, cheaper shipping costs and quicker installation.

- Adjustable Brackets on the back frame allows for The Rack to accommodate all styles of unit heaters, effortless installation and easier service entry.

- A completely redesigned Control Panel resulted in clear access to controls, straightforward wiring process and speedier service time.

- Our New Control Panel will ship straight up. Once on the jobsite the panel will hinge down for wiring, service and easy access.

*New Rack provides convenient carrying

- Our Control Panel has UL approved fittings, whips, switches, terminal block and housing.

*Control Panel in Shipping Position

The Rack™ Energy Rotation System – Guarantees ENERGY SAVINGS while maintaining consistent BUILDING TEMPERATURE.

Features:

- High Energy Savings

- Consistent Building Temperature

- Low Installation Cost

- No Loss of Valuable Floor Space

- Quiet Operation

- Low Maintenance

- Fresh Air Intake Option

In this economy – energy efficient, quality built, and affordable ventilation and air distribution products are critical to keeping building temperatures consistent and energy costs low.

To learn more visit AESRack.com, or contact the Air Energy Systems sales office at (317) 290-8500 or email contact form.

CASE STUDY: Duke Construction used Air Energy “The Rack” ER systems to increase tenant comfort level in the space and reduce energy costs.

Duke Construction wanted the design HVAC contractor to explore new ways to upgrade the low heating efficiencies of standard unit heaters and the constant moving of these heaters in their Type 2 spec buildings.

PROBLEM: Older unit heaters were not providing the comfort level required by tenants for their employees.

PROBLEM: On their Type 2 buildings, Duke had always used unit heaters in their spaces for heating. As a heating system, unit heaters were not only not economical to operate; they were not providing the comfort level required by their tenants for their employees.

SOLUTION: By putting The Rack™ ER systems in the corners, they eliminated any future need to move the systems regardless of how the building space was subdivided. Along with not moving the systems, they increased the comfort level in the space and reduced the energy costs to the tenants.

In this economy – energy efficient, quality built, and affordable ventilation and air distribution products are critical to keeping building temperatures consistent and energy costs low. Duke Construction knows about cost saving The Rack™ ER Units – and now you do too.

SOLUTION: The Rack™ increased the comfort level in the space and reduced the energy costs to the tenants.

To learn more contact the Air Energy Systems sales office at (317) 290-8500 .

The Rack™ models are available in four sizes:

- ER-130-200 : 9,000 cfm – 200,000 btu/hr

- ER-230-400 : 18,000 cfm – 400,000 btu/hr

- ER-142-400 : 16,500 cfm – 400,000 btu/hr

- ER-242-800 : 33,000 cfm – 800,000 btu/hr

![]() Download a copy of The Rack™ brochure.

Download a copy of The Rack™ brochure.

Ideal for Metal Buildings – The Rack™…

Ideal for Metal Buildings – The Rack™…

- Reduces the need for expensive roof structural steel.

- Eliminates roof penetration which causes roof leaks.

- Decreases the quantity of units needed to distribute the conditioned air evenly throughout the space.

- Maintains consistent temperatures throughout the work environment eliminating the need for expensive discharge duct work.

- Lowers installation costs with gas and electrical piping.

- Saves utility expenses in both natural gas and electrical consumption.

- Case Studies prove The Rack™ is the best solution for Metal Buildings.

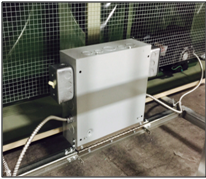

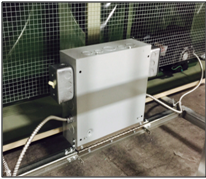

The Newly 2016 Renovated Rack

- Switching from Angle Iron to a Galvanized Tube Steel Frame led to lighter overall weight, elimination of wooden pallet, cheaper shipping costs and quicker installation.

- Adjustable Brackets on the back frame allows for The Rack to accommodate all styles of unit heaters, effortless installation and easier service entry.

- A completely redesigned Control Panel resulted in clear access to controls, straightforward wiring process and speedier service time.

- Our New Control Panel will ship straight up. Once on the jobsite the panel will hinge down for wiring, service and easy access.

*New Rack provides convenient carrying

- Our Control Panel has UL approved fittings, whips, switches, terminal block and housing.

*Control Panel in Shipping Position

The Rack™ Energy Rotation System – Guarantees ENERGY SAVINGS while maintaining consistent BUILDING TEMPERATURE.

Features:

- High Energy Savings

- Consistent Building Temperature

- Low Installation Cost

- No Loss of Valuable Floor Space

- Quiet Operation

- Low Maintenance

- Fresh Air Intake Option

In this economy – energy efficient, quality built, and affordable ventilation and air distribution products are critical to keeping building temperatures consistent and energy costs low.

To learn more visit AESRack.com, or contact the Air Energy Systems sales office at (317) 290-8500 or email contact form.

07 Jul / 2015

The Newly Renovated Rack

- Switching from Angle Iron to a Galvanized Tube Steel Frame led to lighter overall weight, elimination of wooden pallet, cheaper shipping costs and quicker installation.

- Adjustable Brackets on the back frame allows for The Rack to accommodate all styles of unit heaters, effortless installation and easier service entry.

- A completely redesigned Control Panel resulted in clear access to controls, straightforward wiring process and speedier service time.

- Our New Control Panel will ship straight up. Once on the jobsite the panel will hinge down for wiring, service and easy access.

*New Rack provides convenient carrying

- Our Control Panel has UL approved fittings, whips, switches, terminal block and housing.

*Control Panel in Shipping Position

The Rack™ Energy Rotation System – Guarantees ENERGY SAVINGS while maintaining consistent BUILDING TEMPERATURE.

Features:

- High Energy Savings

- Consistent Building Temperature

- Low Installation Cost

- No Loss of Valuable Floor Space

- Quiet Operation

- Low Maintenance

- Fresh Air Intake Option

In this economy – energy efficient, quality built, and affordable ventilation and air distribution products are critical to keeping building temperatures consistent and energy costs low.

To learn more visit AESRack.com, or contact the Air Energy Systems sales office at (317) 290-8500 or email contact form.

02 Jun / 2015

RACK™ in the Rebates with Air Energy Systems, Inc.

Air Energy’s The Rack™ energy rotation systems save businesses thousands of dollars in energy savings and thousands more in rebates.

Check out a few impressive examples below:

Vectren offers a Custom Incentive Rebate Program in all of their service areas around the state. This program offers up to $1.00/therm for projects saving more than 25,000 therms,

$.75/therm for projects between 7,500-24,999 therms and a maximum payout amount of $50,000 per project. Air Energy System’s Rack Unit is the only technology that received the maximum rebate on multiple projects.

Allpoints #6 (950,000’) installed (8) ER-242-800 Rack Units and (2) Rupp Ram 30 MAU, this system saved the owner 93,196 therms compared to a traditional heating system. This savings resulted in a $50,000 check to the owner.

Allpoints #6 (950,000’) installed (8) ER-242-800 Rack Units and (2) Rupp Ram 30 MAU, this system saved the owner 93,196 therms compared to a traditional heating system. This savings resulted in a $50,000 check to the owner.

*This program is run by CleaResult

Citizens Energy Group offers a Custom Rebate Program in their service area, Marion Country. Project payouts are $0.75 for savings under 7,500 therms and $1.00 for saving over 7,500 therms. The max payout increased 30% to $35,000 rebate amount. The Rack Unit received over 70% of all the Natural Gas Custom Rebates for Citizens and Vectren in 2014.

Prologis (96,000’) installed (3) ER-242-800 Rack Units with (2) Fresh Air Intake Kit. Fresh air is brought into the facility through The Rack Unit to meet ASHRAE 62.1 indoor air quality standards. This system was also designed to provide (2) Air Changes per hour for summer ventilation. Citizens Energy Group issued an $11,923 rebate incentive check to Prologis.

*This program is run by CleaResult

Indianapolis Power and Light Company offers a Custom Rebate Program in their service area, Marion County. IPL pays $.07/kWh saved and has a maximum limit of $100,000 per technology. IDI – Ameriplex 2 (461,592’) installed (6) ER-242-800 Rack Units and (2) Rupp Ram 22 MAU, this system utilizes an Energy Management System to reduce kWh usage. IDI saved 248,714 kWh which amounted to an IPL Rebate amount of $17,410

*This program is run by CleaResult

Duke Energy offers a Custom Rebate Program available to all qualifying businesses in their service area. Duke pays up to $.10/kWh saved and has a maximum limit of $500,000 per project.

Walmart (1,228,500’) installed (18) ER-242-800 and (40) 25 Ton Roof Top Units, this system evenly distribute the heat and cooling throughout the facility. The Rack Units eliminate stratification which allows the RTU to cycle off and led to massive kWh savings. Walmart saved 1,726,000 kWh which amounted to a Duke Rebate check of $60,000.

In this economy – energy efficient, quality built, affordable ventilation and air distribution products are critical to keeping building temperatures consistent and energy costs low. The Rack™ can be your ideal solution.

METAL BUILDING SOLUTION: The Rack™ models are available in four sizes:

ER-130-200 : 9,000 cfm – 200,000 btu/hr

ER-230-400 : 18,000 cfm – 400,000 btu/hr

ER-142-400 : 16,500 cfm – 400,000 btu/hr

ER-242-800 : 33,000 cfm – 800,000 btu/hr

Learn more about The Rack™ here, or Contact Air Energy Systems today at (317) 290-8500

The Rack™ is Manufactured in the USA by Air Energy Systems, Inc.

31 Jan / 2015

AES Head Office Improvements

Air Energy Systems (AES) recently completed improvements to its Indianapolis head office location.

Old carpet was removed exposing 100+ year old oak flooring which was then sanded and finished. New paint and fixtures were added to make the workspace both functional and attractive.

Improvements were managed by longtime New Augusta resident James Warriner. Much thanks also goes to Dotty Maher for planning and overseeing the improvements. Collin Maher (AES Sales) also lent his tremendous energy and talent to the project.

As our company moves comfortably into the new millennium, Air Energy Systems remains a market leader in ventilation equipment, air distribution products, radiant heaters, make-up air units, and energy rotation units. For more information about our products and services, please contact us today

The Rack™ Ventilation and Air Distribution “ER Unit” guarantees ENERGY SAVINGS while maintaining consistent BUILDING TEMPERATURE’s.

Ideal for Metal Buildings The Rack™

- Reduces the need for expensive roof structural steel.

- Eliminates roof penetration which causes roof leaks.

- Decreases the quantity of units needed to distribute the conditioned air evenly throughout the space.

- Maintains consistent temperatures throughout the work environment eliminating the need for expensive discharge duct work.

- Lowers installation costs with gas and electrical piping.

- Saves utility expenses in both natural gas and electrical consumption.

- Case Studies prove The Rack™ is the best solution for Metal Buildings.

In this economy – energy efficient, quality built, affordable ventilation and air distribution products are critical to keeping building temperatures consistent and energy costs low. The Rack™ can be your ideal solution.

METAL BUILDING SOLUTION: The Rack™ models are available in four sizes:

ER-130-200 : 9,000 cfm – 200,000 btu/hr

ER-230-400 : 18,000 cfm – 400,000 btu/hr

ER-142-400 : 16,500 cfm – 400,000 btu/hr

ER-242-800 : 33,000 cfm – 800,000 btu/hr

Learn more about The Rack™ here, or Contact Air Energy Systems today at (317) 290-8500

Duke Construction used Air Energy “The Rack” ER systems to increase tenant comfort level in the space and reduce energy costs.

CASE STUDY:

CUSTOMER: Duke Construction

LOCATION: Indianapolis, IN

DESIGN SPECIFICATIONS: Duke Construction wanted the design HVAC contractor to explore new ways to upgrade the low heating efficiencies of standard unit heaters and the constant moving of these heaters in their Type 2 spec buildings.

PROBLEM: Older unit heaters were not providing the comfort level required by tenants for their employees.

PROBLEM: On their Type 2 buildings, Duke had always used unit heaters in their spaces for heating. As a heating system, unit heaters were not only not economical to operate; they were not providing the comfort level required by their tenants for their employees.

SOLUTION: By putting The Rack™ ER systems in the corners, they eliminated any future need to move the systems regardless of how the building space was subdivided. Along with not moving the systems, they increased the comfort level in the space and reduced the energy costs to the tenants.

In this economy – energy efficient, quality built, and affordable ventilation and air distribution products are critical to keeping building temperatures consistent and energy costs low. Duke Construction knows about cost saving The Rack™ ER Units – and now you do too.

SOLUTION: The Rack™ increased the comfort level in the space and reduced the energy costs to the tenants.

To learn more contact the Air Energy Systems sales office at (317) 290-8500 .

The Rack™ models are available in four sizes:

- ER-130-200 : 9,000 cfm – 200,000 btu/hr

- ER-230-400 : 18,000 cfm – 400,000 btu/hr

- ER-142-400 : 16,500 cfm – 400,000 btu/hr

- ER-242-800 : 33,000 cfm – 800,000 btu/hr

Case Study:

Customer: Honda of Indiana

Location: Greensburg, Indiana

Project Challenge:

Honda’s original heating/cooling design used direct fired equipment incorporated with cooling coils and sheet metal distribution ducting. The warehouse continually exceeded their budget for temperature control and considered eliminating the cooling function all together.

Air Energy System’s (The Rack™) Solution:

AES recommended installing eight 60-ton ground mounted gas/electric rooftop units along with eight (The Rack™) ER-248 ceiling hung air rotation units into the facility. The equipment design increased the air distribution from 192,000 cfm to 400,000 cfm.

Results:

By installing (8) 60-ton ground mounted rooftop units with (8) ER-248 The Rack™ air turn-over units, Honda experienced the following results:

- Honda was able to eliminate their costly sheet metal distribution ducting

- Honda experienced a $500,000 cost savings

- Honda warehouse has less than a 2-3° temperature difference anywhere in the facility.

Honda liked the operation of “The Rack™” ER units so well – they installed the same ER units in their next facility located in Sidney, OH – and success breeds more success – as Honda is also installing even more “The Rack™” ER Units in another warehouse facility planned for 2014!

- Customer: Honda of Indiana Location: Greensburg, IN

- Utilizing (8) ER-248 (aka “The Rack™) Honda Experienced $500K in Cost Savings

- Facility Warehouse 400,000’ x 32’ High Winter Operation 68 °– 0 Summer Operation 93° – 78°

In this economy – energy efficient, quality built, and affordable ventilation and air distribution products are critical to keeping building temperatures consistent and energy costs low. Honda knows about cost saving “The Rack™” ER Units …and now you do too.

To learn more visit AESRack.com, or contact the Air Energy Systems sales office at (317) 290-8500 or email contact form.

08 Oct / 2013

Facility Not Warm Enough? Solution: The Rack™

Is your facility warm enough?

The Rack™ Guarantees ENERGY SAVINGS while maintaining consistent BUILDING TEMPERATURE.

The Rack™ can meet your heating demands whether heating a 10,000 square foot steel building or a 600,000 sq ft multi-tenant structure. The Rack™ utilizes the industry’s most energy efficient heater and combines it with a ceiling hung air turn-over unit.

- High Energy Savings

- Consistent Building Temperature

- Low Installation Cost

- No Loss of Valuable Floor Space

- Quiet Operation

- Low Maintenance

- Fresh Air Intake Option

Basic RACK models are available in four sizes:

- ER-130-200 : 9,000 cfm – 200,000 btu/hr

- ER-230-400 : 18,000 cfm – 400,000 btu/hr

- ER-142-400 : 16,500 cfm – 400,000 btu/hr

- ER-242-800 : 33,000 cfm – 800,000 btu/hr

Additional features of The RACK Heating Energy Rotation Unit include:

- 93% efficient…truly the first “GREEN HEATING SYSTEM”

- Offers ultimate flexibility for multi tenant buildings as square footage changes in size and usage

- Utility savings up to 40%…1 ER unit can replace multiple standard unit heaters – using the same flue vent piping… ideal for retro-fit projects

- De-stratifies heated ceiling air to floor level

- Utilizes any heat source: natural gas, steam or hot water or electric unit heaters

- Fresh outside air can be supplied through roof mounted intake hoods or side wall intake louvers or dampers

The Rack™ is Manufactured in the USA by Air Energy Systems, Inc.

In this economy – energy efficient, quality built, and affordable ventilation and air distribution products are critical to keeping building temperatures consistent and energy costs low.

To learn more visit AESRack.com, or contact our sales office at (317) 290-8500 or email contact form.