The Energy Rotation System

Guarantees ENERGY SAVINGS while maintaining consistent BUILDING TEMPERATURE

Product features:

- High Energy Savings

- Consistent Building Temperature

- Low Installation Cost

- No Loss of Valuable Floor Space

- Quiet Operation

- Low Maintenance

- Fresh Air Intake Option

Bry Belly

Camp Atterbury Building

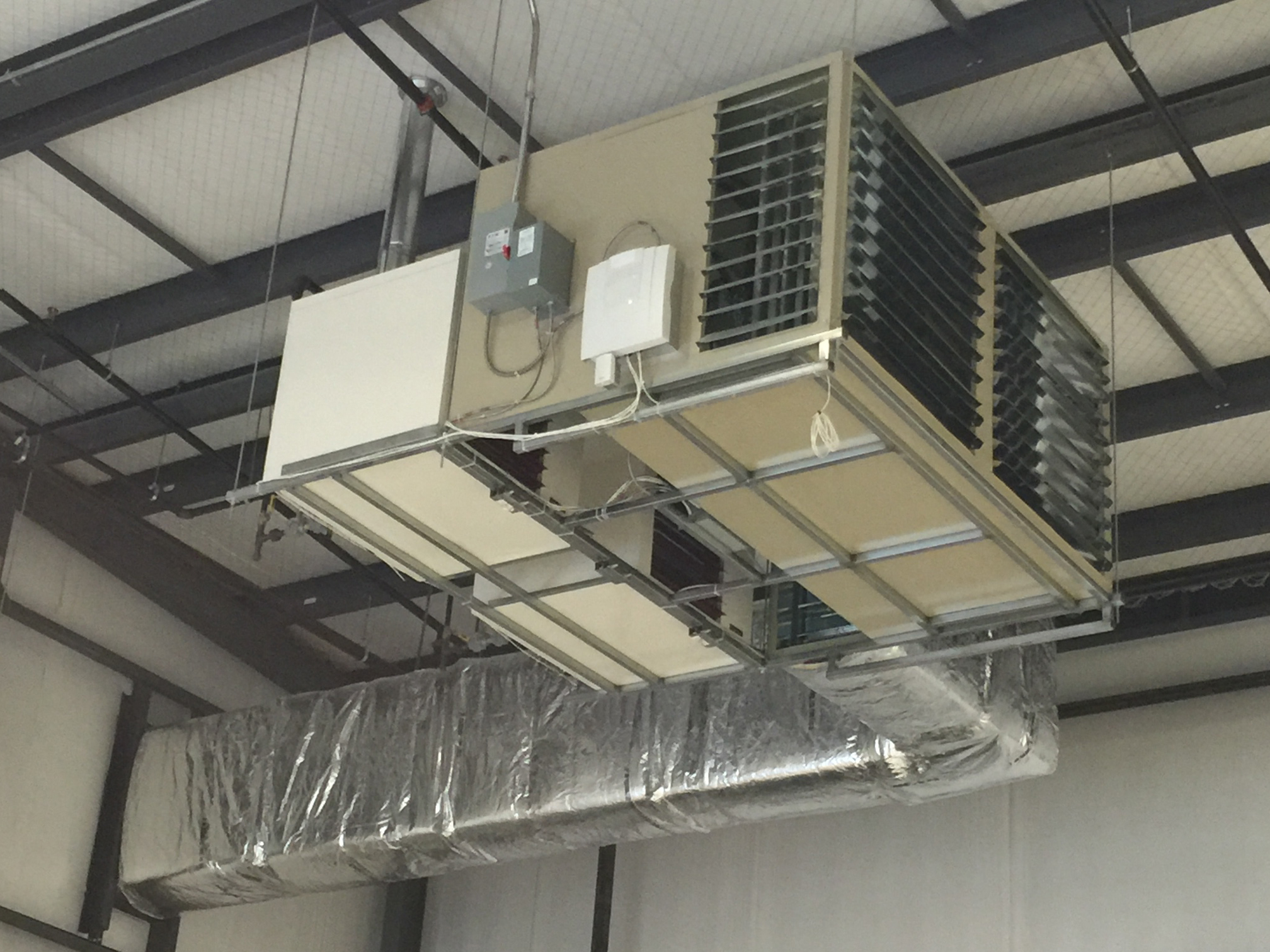

The Rack™

Heating Applications

THE RACK can meet your heating demands whether heating a 10,000 square foot steel building or a 600,000 sq ft multi-tenant structure. THE RACK utilizes the industry’s most energy efficient heater and combines it with a ceiling hung air turn-over unit.

The Energy Rotation (ER) unit has two distinct functions. First, the unit-heater controlled by the thermostat, cycles on and off based on the temperature demands of the building. And secondly, the ER’s rotation fan runs continuously distributing heated air evenly throughout the space.

Basic RACK models are available in four sizes:

- ER-130-200 : 9,000 cfm – 200,000 btu/hr

- ER-230-400 : 18,000 cfm – 400,000 btu/hr

- ER-142-400 : 16,500 cfm – 400,000 btu/hr

- ER-242-800 : 33,000 cfm – 800,000 btu/hr

Additional features of the RACK Heating Energy Rotation Unit include:

- 93% efficient…truly the first “GREEN HEATING SYSTEM”

- Offers ultimate flexibility for multi tenant buildings as square footage changes in size and usage

- Utility savings up to 40%…1 ER unit can replace multiple standard unit heaters – using the same flue vent piping… ideal for retro-fit projects

- De-stratifies heated ceiling air to floor level

- Utilizes any heat source: natural gas, steam or hot water or electric unit heaters

- Fresh outside air can be supplied through roof mounted intake hoods or side wall intake louvers or dampers

Heating & Cooling Applications

THE RACK, incorporated with conventional heating and cooling roof-top units, provides the most cost efficient method of maintaining temperatures in a facility.

Utilizing any manufacture’s equipment, THE RACK mixes the unit’s discharged air with large volumes of returned plant air. The ceiling hung installation design allows THE RACK to turn over and distribute air with minimal electrical consumption…while preserving your valuable floor space.

Example: 25 ton roof top units have a discharge air flow of 10,000 cfm. By discharging the 10,000 cfm into the ER-242, air circulation increases to 33,000 cfm… resulting in even temperatures through the facility.

This process will eliminate hot and cold spots associated with standard heating or heating/cooling systems. The building maintains even temperatures and increases the comfort level for employees.

Steel Building & Precast Facilities:

- Reduces the need for expensive roof structural steel (Steel Buildings)

- Eliminates roof penetration which causes roof leaks (Steel Buildings)

- Decreases the quantity of units needed to distribute the conditioned air evenly throughout the space

- Maintains consistent temperatures throughout the work environment eliminating the need for expensive discharge duct work

- Lowers installation costs with gas and electrical piping

- Saves utility expenses in both natural gas and electrical consumption

Orora

Dow RTUs

The Rack – Unit Specifications

The Rack – Installation Comparisons

The Rack – Features and Options

We welcome the opportunity to partner with you on your next project and invite you to browse our website and contact us – or call (317) 290-8500 with any question you may have about your equipment needs.